English

BS

Brightsail

| Availability: | |

|---|---|

| Quantity: | |

Introduction

BS cryogenic mill adopts external media freezing method.

Some materials cannot be crushed at normal temperature, and the freezing crush method will solve this problem.

Application of BS cryogenic grinding machine

1) Chemical industry and coating field;

2) Food and health care products;

3) Recycling: low melting point plastics, high self-lubricating materials, waste rubber, raw rubber and raw rubber;

4)The hot melt adhesive like EVA EAA TPU LDPE and other low melting point colloids.

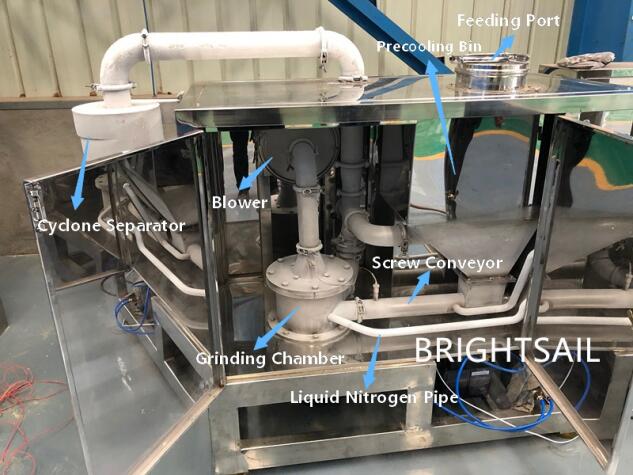

Structure of BS cryogenic mill

1、 BS cryogenic mill uses precooling silo to precool the materials.

Precooling silo is equipped with precision liquefied gas vaporizer to forcibly cool materials during Liquid gas gasification.

2、 It adopts a screw feeder to send materials which have reached uniform cooling embrittlement into mill chamber.

3、 The independent rolling pair ensures the normal operation of the machine in the low temperature environment.

Refrigerant re-injection is to compensate the heat generated in the crushing process.

The refrigerant injection amount is adjusted through the low-temperature valve.

4、 Refrigerant compensated re-injection offsets the heat generated by the material in the crushing process.

The refrigerant injection amount is adjusted through the low temperature valve.

The high-pressure air flow generated during the crushing of the material and the air flow of refrigerant pressure loss expansion are discharged from the chamber through the rotating window of the static classifier of the crusher. Powder reached target size enters the discharge system along the same airflow, and coarse powder impacts the static classifier blade and bounces back to the mill chamber,so preliminary classification effect is achieved.

5、 Discharge traction system: air traction is adopted to discharge the crushed materials from the host through the pipeline.

6、 The inclined angle discharge system is used for discharging, and the inclined spiral discharge system ensures that the air of the cyclone separator will not flow out of the discharge port.

Working Method

Grind method of BS cryogenic grinding mill

Heat exchange between cold source and materials will reduce the temperature of material and make the material into brittle.

The brittle material is impacted,sheared and rubbed in the mill chamber,then it becomes fine particles which can reach micron level (600~2000 mesh).

The cooling agent can be selected according to the feature of material.For example, if liquid nitrogen is used as the refrigerant, its lowest cooling temperature can reach minus 196 ℃, and its cooling speed is very fast.

Liquid nitrogen is the best choice for materials request rapid cooling speed and low embrittlement temperature.

Compressed air or cold air conditioner can also be used to exchange heat with materials with low requirement on embrittlement temperature.

This is picture of our BS-200 cryogenic milling machine

Advantages

Advantage of BS cryogenic grinding mill

This machine uses a high-performance liquefied gas vaporizer to generate heat exchange between refrigerant and materials during the gasification process. The residual cold air is collected by means of back-flow.

Each part uses pipe valves to adjust the air compensation of the back-flow cold air to the crusher cavity.

The best effect has been achieved in the pre-cooling, closed transmission, closed classification, discharge back-flow, refrigerant utilization, power source mechanism, and heat preservation during crushing and transportation of materials.

Technical Data

Technical Data of BS Cryogenic Mill Machine

Model | BS-200 | BS-400 | BS-500 | BS-800 | BS-1000 |

Total power (KW) | 14.5 | 37.3 | 65.5 | 91.5 | 152.5 |

Medium | Liquid nitrogen | ||||

Temperature(℃ ) | -196~0 | ||||

Fineness(mesh) | 10~700 (depends on materials) | ||||

Capacity(kg/h) (depends on materials) | 10~100 | 50~200 | 100~800 | 200~1500 | 400~2000 |

working videos

This is video of our BS-200 cryogenic grinding mill

This is video of our BS-500 cryogenic mill machine

Tel: +8615961653782

Fax:+86-510-86389258

Phone: +8615961653782

E-mail: info@brightsail-asia.com

Skype: jewel.qian

Whatsapp:+8615961653782